When it comes to packaging, accuracy matters more than most businesses realize. A simple measuring mistake can lead to higher shipping costs, damaged goods, or wasted materials. Whether you sell online or supply wholesale, understanding the length width height of your box correctly is essential for product protection and cost efficiency.

Why Box Measurements Are So Important

Choosing the right box size is not only about looks , it’s about performance and savings. Incorrect dimensions can cause shipping miscalculations, inefficient stacking in storage, and even product damage during delivery. On the other hand, well-measured packaging ensures your products fit securely and arrive safely.

Understanding Box Dimensions

The term “length width height box” simply refers to the three key measurements that define a package. Here’s what each dimension means:

Length: The longest side, usually the front-facing one.

Width: The shorter side of the base, perpendicular to the length.

Height (or depth): The vertical distance from bottom to top.

In packaging, the standard format is always L × W × H, which helps avoid confusion between manufacturers and shipping partners.

How to Measure a Box Properly

You don’t need special tools to measure a box correctly — just a tape measure or ruler and a few minutes of focus.

Follow these simple steps:

Place your box on a flat surface.

Measure the inside dimensions if you want to know the internal capacity for your product.

Measure the outside dimensions if you need shipping estimates.

Stick to one unit (inches or centimeters) to keep measurements consistent.

For example, if your box’s inside dimensions are 18 × 12 × 8 inches, that number represents how much space your product occupies.

Inside vs. Outside Dimensions

It’s important to know which measurement type you’re using:

Inside dimensions determine how well your product fits inside the box.

Outside dimensions are used for calculating shipping and warehouse stacking.

Mixing them up can lead to ordering boxes that are too small inside or too costly to ship outside.

Avoid These Common Measuring Mistakes

Many businesses make avoidable mistakes when taking box measurements:

Measuring from the wrong edge.

Confusing width and height.

Ignoring space for padding or inserts.

Forgetting to round up measurements for shipping companies.

Taking an extra minute to double-check can save you money and frustration later.

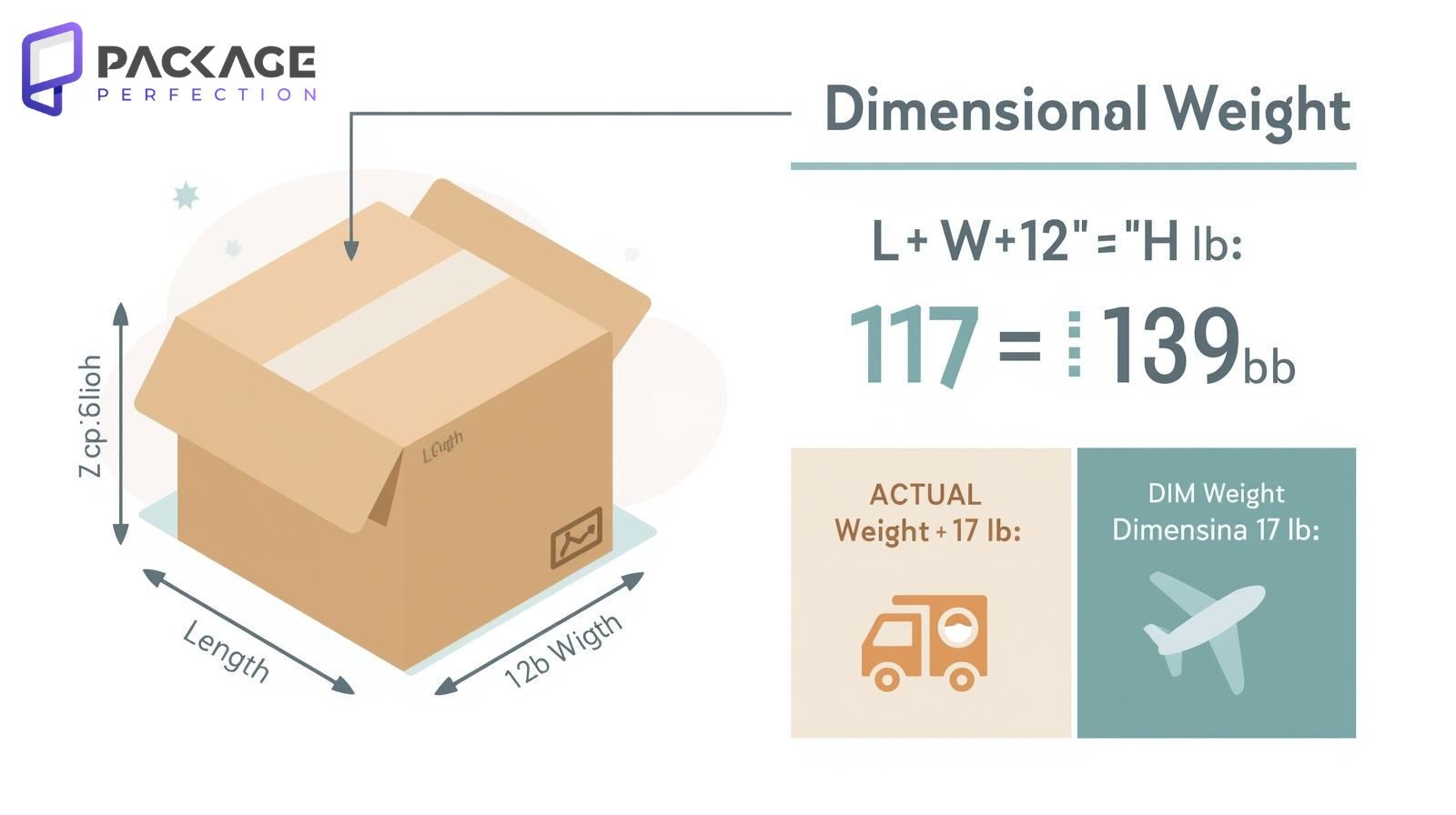

Dimensional Weight (DIM) and Shipping Costs

Shipping companies such as FedEx, UPS, and DHL use dimensional weight to calculate charges. It’s based on the space your box occupies, not just its actual weight.

The formula is:

(Length × Width × Height) ÷ DIM Divisor

For example, a box measuring 20 × 12 × 10 inches equals 2400 cubic inches. Dividing by 139 (the DIM divisor used by major carriers) equals about 17 pounds — meaning even a 5-pound product could be billed as 17 pounds if the box is large.

Smart Tips for Better Measurements

Measure twice before finalizing your order.

Keep a record of all product and box sizes.

Add space for cushioning if your product is fragile.

Use a reliable measuring tool to ensure accuracy.

Final Thoughts

Accurate packaging measurements are not just a technical step they’re a smart business strategy. When your boxes are sized correctly, you save on shipping, reduce damage risk, and present a professional image to your customers.

If you’re unsure how to measure your length width height box, consider consulting a reliable packaging provider like Package Perfection. They specialize in helping businesses design custom-sized packaging that fits perfectly, ships affordably, and enhances brand presentation.